As the cost of home elevators continue to improve they are becoming more of a reality for home owners. That being said, the quality of some systems is better than others and one of the main things a home owner feels every day is the “ride quality” or in some cases the poor ride quality. This can often be avoided by choosing a guide rail system that will perform well and avoid costly maintenance over the long term.

What is poor ride Quality?

Poor ride quality is characterized by vibration, sudden unexpected motion, and noise. Two of the most common adversaries of a smooth ride are rail misalignment and unbalanced cars. While the tendency is to point the finger at the elevator contractor, the real culprits are often in Mother Nature’s hands.

What are the culprits of misalignment?

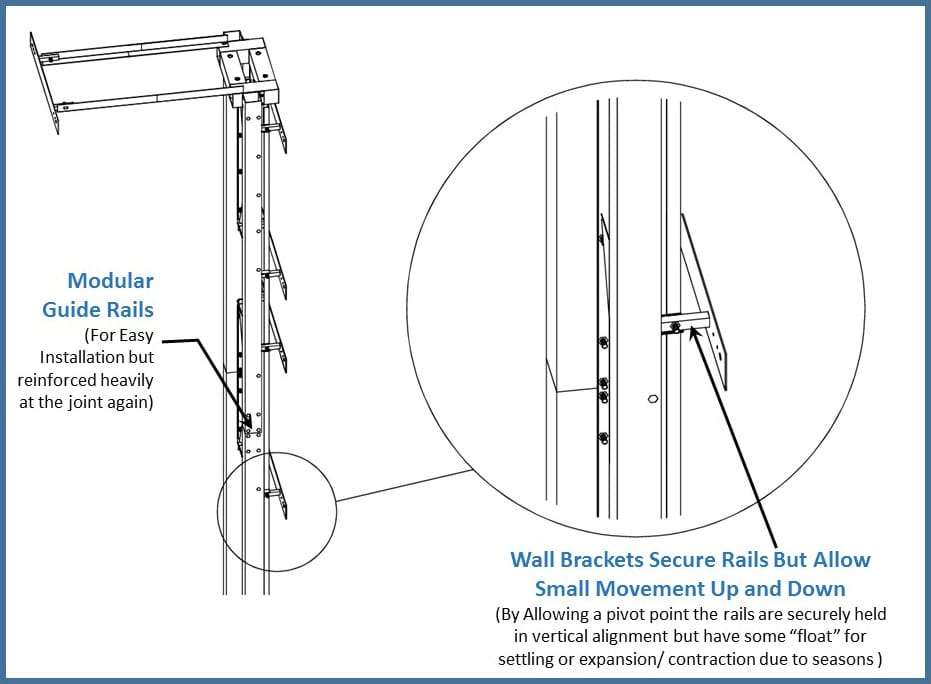

After the construction of a home, the drying of concrete, settling of the building, and the drying of wood products can all greatly affect alignment of guide rails in relation to the building and to each other (there are usually 2 guide rails).

In some cases these changes can induce a “curve” to the rail. This happens if the rail is fixed to the walls in such a way that the rail is not able to be supported in the lateral (side to side) direction. Many rail system designs the rails can even move relative to each other causing premature wear, noise and, in some extreme cases, “jamming”.

All of these effects produce a poor ride quality that the home owner can feel during operation and can also lead to increased maintenance and repair costs to remedy the situation.

Pros and Cons of Rail System Types

Some guide rails are manufactured from a solid material section like a T-Rail or J-Rail. One problem with these types of guide rails is the significant weight and price to achieve the desired level of strength and rigidity that will allow your home elevator to perform well both today and over the long term.

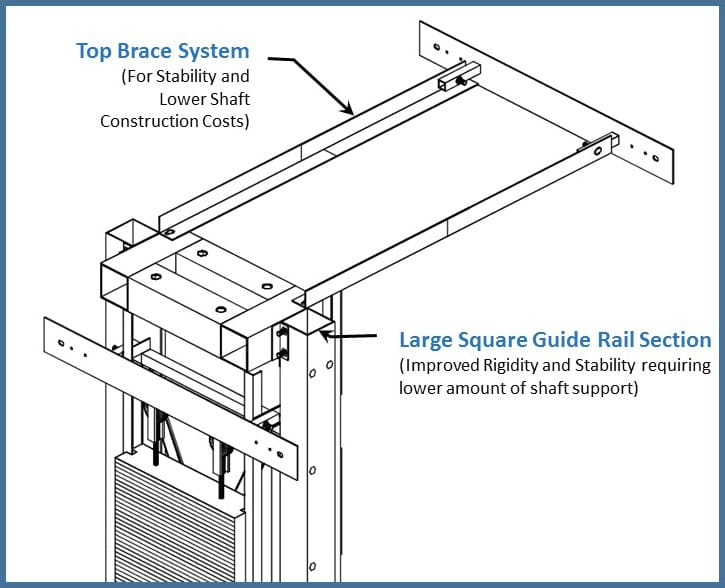

Hollow section guide rails, are lighter for the level of strength and rigidity they can offer, however, the section needs to be designed to ensure that the wall thickness of the section is sufficient to withstand any “gripping forces” that may be present during normal operation and the application of safety braking scenarios…..Not All designs are equal and the devil is in the details.

High Quality, Low Noise and Low Maintenance Operation

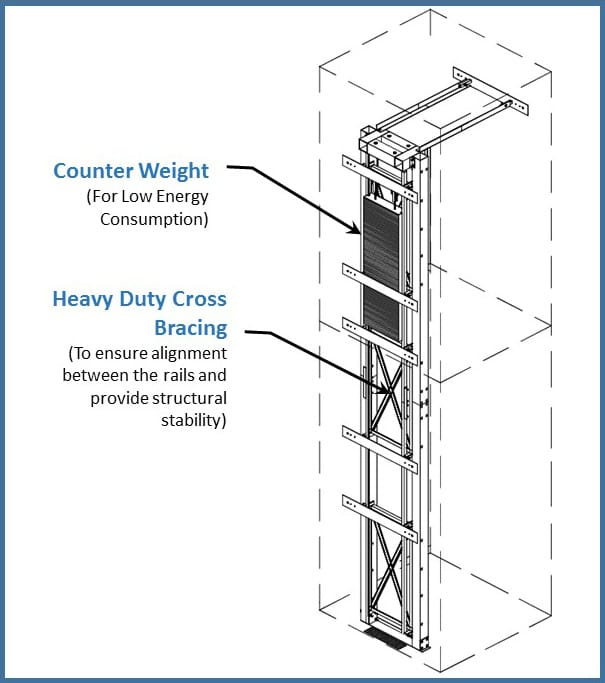

RAM’s innovative guide rail system is a hollow section large square tubing with the majority of support being provided by the foundation. This innovative design combats all of the above problems by being designed as a fully integrated support system.

This means the alignment between the rails and at the section points is not dependent on the wall supports and thus eliminates the potential side to side misalignment. RAM’s design also eliminates the misalignment risk at the section points that is typically present in standard T-rail type systems.

If you want high quality, low noise, and low maintenance operation, the RAM guide rail system is simply the best guide rail system on the market for residential and low rise commercial applications . We have even seen the RAM system function perfectly after small earthquake events in some locations but, please note that every elevator should be inspected after significant events such as an earthquake to ensure safe operation.

RAM Guide Rail System

- Fully Integrated Design

- Large Square Tubes with Optimized wall thickness

- Heavy Duty Cross Bracing to ensure alignment between rails

- Long life stability once installed

- Support from shaft walls with ability to withstand small building movements

Alternate Guide Rail Systems

- Typically T-Rail or J-Rail

- Solid section

- Limited or No Cross Bracing to maintain alignment

- Reliant on building construction and stability for guide rail alignment

- Difficulty handling small building movements